The impact on the farmer

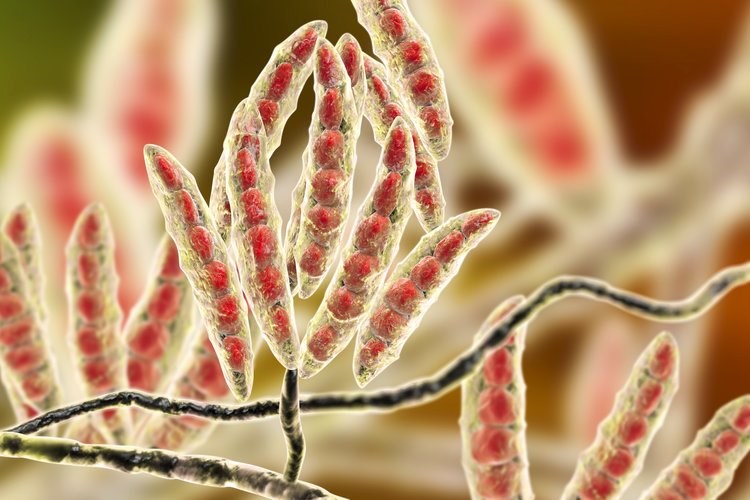

Mycotoxins can present food safety challenges to animals and humans by contamination of grains, animal products and by-products.

If not managed properly, mycotoxins can exceed non-toxic levels and start to impact production parameters, such as daily feed intake, average daily gain, milk or egg yield and, in extreme cases, increase mortality.

Young animals, such as broilers, piglets and calves, are especially susceptible to the impact of mycotoxins. However, chronic low levels of mycotoxins can have significant effects in long living animals as well.

Issues with toxin contamination in human food products have been reported in different parts of the world. These include the presence of aflatoxin M1 in milk, ochratoxin A in kidney and pork products, and T-2 toxin in eggs.