How to recognise

Several steps in the feed production process influence moisture content. This may lead to process loss and operational inefficiencies such as decreased pellet durability and reduced throughput (also referred to as shrinkage or loss of bulk).

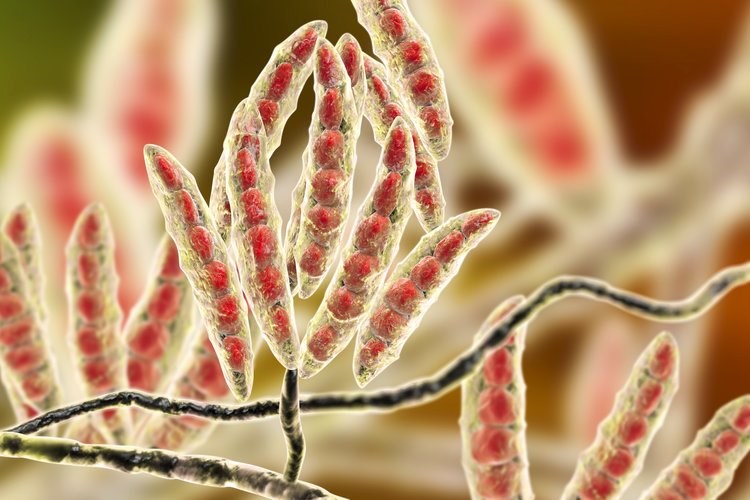

A common solution is adding water to compensate for losses experienced during production. However, this increases water activity (aW), resulting in higher availability of moisture for harmful microbes to grow.

The challenge is to find a solution to improve moisture levels without increasing the chances of microbial growth. Ensuring a deep penetration of moisture inside the feed particle requires surface tension reduction, while simultaneously adding solutions to prevent the growth of harmful microbes, important for a longer shelf life and nutritional quality.

Impact for feed mill

Ineffective management of process moisture can cause serious problems in the quality of the final feeds. Possible issues include reduced shelf life, inconsistent nutritional value and increased levels of dust by broken pellets, all of which can impact animal performance and your brand’s image.

Contact Us

Our Selko Feed Safety & Milling Efficiency team includes:

Lauren Judd - Technical Sales Manager Feed Safety

Ricky Cairns - Field Service and Callibration Engineer